+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

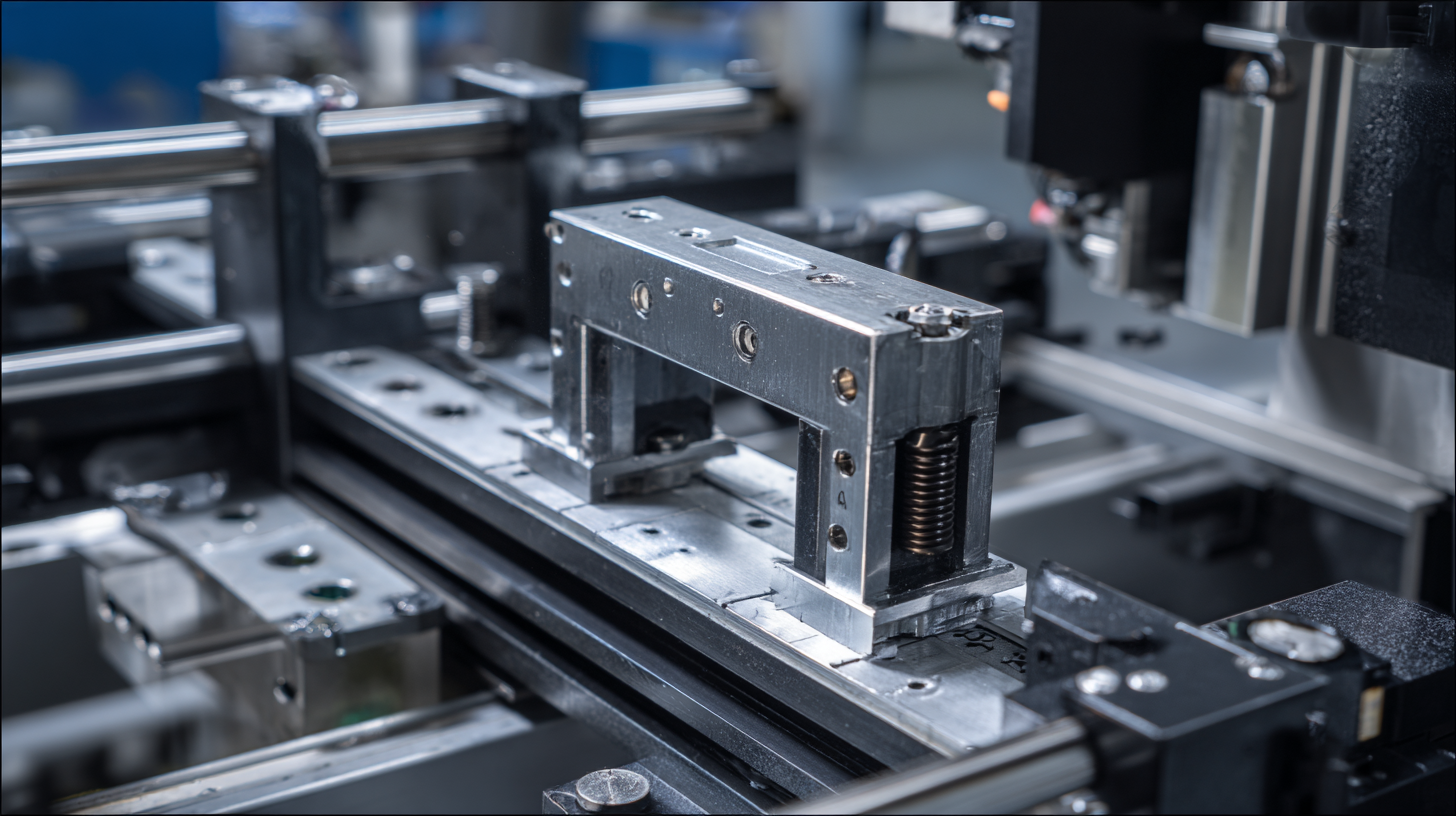

In the competitive landscape of global manufacturing, the robustness and reliability of assembly components play a crucial role in operational success. Among these, the Frame Support Bracket stands out as an essential element that can significantly enhance productivity and workflow efficiency.

According to a recent report from Markets and Markets, the global manufacturing equipment market is projected to reach $450 billion by 2025, indicating a vast reliance on quality components. A well-designed Frame Support Bracket not only contributes to structural integrity but also optimizes assembly processes, reducing downtime caused by equipment failures.

As manufacturing facilities strive to embrace Industry 4.0 and improve their overall efficiency, understanding the importance of this seemingly simple component can lead to monumental advancements in productivity and cost savings, aiding businesses in maintaining their competitive edge in the market.

In modern manufacturing, the significance of frame support brackets cannot be overstated, particularly in sectors like aerospace and automotive. As highlighted in recent studies, the shift towards metal additive manufacturing is transforming the aerospace industry, allowing for the creation of complex geometries while reducing weight—a crucial element for efficiency. Frame support brackets enhance structural integrity and stability, ensuring that manufactured parts maintain their precise shapes during the production process and beyond.

Moreover, the push for lightweight materials in automobile manufacturing is leading to an increased application of advanced frame support solutions. Next-generation automobiles utilizing high-strength steels and alloys depend on robust frame support brackets that can withstand the stresses during assembly and operation. This relationship is particularly evident as electric vehicle manufacturers embrace mechanical fastening techniques, which offer numerous advantages in ensuring the durability and reliability of vehicle structures.

Tips for manufacturers: Invest in high-quality frame support brackets tailored to your specific requirements. Consider materials that align with your product's weight and strength needs. Regularly assess the performance of your support systems to maintain the quality of your manufacturing processes. Additionally, stay informed on emerging technologies and materials that can further enhance production efficiency and product longevity.

When looking at the intricate world of global manufacturing, the role of the best frame support brackets cannot be overstated. These essential components contribute significantly to structural integrity and operational efficiency. A key feature of high-quality frame support brackets is their durability, often made from materials such as high-grade steel or aluminum alloys. According to a report by Smithers Pira, the global demand for durable manufacturing attachments is expected to grow by 7% annually over the next five years, highlighting the importance of investing in reliable hardware.

Another critical aspect is adaptability; top-tier brackets support various frame configurations, accommodating a range of industrial applications. Data from MarketsandMarkets indicates that the versatility in manufacturing components reduces downtime by as much as 15%, emphasizing the importance of adjustable designs that cater to diverse production setups. Additionally, modern frame support brackets often feature corrosion resistance, ensuring longevity even in harsh environments. By understanding these key features, manufacturers can make informed decisions that enhance their operational frameworks and lead to overall manufacturing success.

The demand for high-quality frame support brackets is experiencing significant growth, driven by several market trends in global manufacturing. According to a report by MarketsandMarkets, the global structural steel market is projected to reach USD 215.2 billion by 2027, expanding at a CAGR of 6.8%. This surge is propelled by the increasing need for durable and reliable framing solutions in various applications, from construction to automotive industries. Consequently, quality frame support brackets are essential for ensuring structural integrity and longevity, making them a critical component in manufacturing processes.

Additionally, the push towards sustainable manufacturing practices is influencing the demand for innovative frame support solutions. Research from Fortune Business Insights highlights that the green building materials market is expected to grow from USD 260 billion in 2020 to USD 610 billion by 2027, which indicates a shift towards environmentally-friendly materials. As manufacturers strive to enhance the sustainability of their products, investing in high-quality frame support brackets becomes vital for compliance with rigorous standards, as well as for meeting customer expectations for eco-friendliness. Thus, the evolution of industry standards and consumer preferences positions frame support brackets as pivotal elements in the manufacturing landscape.

In the fast-paced environment of global manufacturing, operational efficiency is paramount. One often-overlooked component that significantly contributes to this efficiency is the frame support bracket. These brackets provide essential structural support, ensuring that machinery and equipment operate smoothly and reliably. By stabilizing frameworks, they minimize vibrations and misalignments that can lead to costly downtime. When equipment is securely mounted, manufacturers can enhance production speeds and maintain consistent quality, which is crucial in today's competitive landscape.

Moreover, frame support brackets facilitate agile manufacturing processes. As production demands fluctuate, the ability to quickly reconfigure layouts is vital. With robust brackets in place, companies can adapt their manufacturing lines with ease, allowing them to pivot quickly to meet market demands without compromising safety or efficiency. This flexibility not only increases responsiveness but also contributes to the overall resilience of manufacturing operations. In essence, investing in high-quality frame support brackets is a strategic move that can yield significant returns through improved efficiency and adaptability in a global market.

| Reason | Description | Impact on Efficiency | Example |

|---|---|---|---|

| Structural Integrity | Frame support brackets enhance the stability of structures. | Reduces maintenance costs by providing long-lasting support. | Used in heavy machinery to prevent collapse. |

| Time Efficiency | Quicker assembly and disassembly of structures. | Increases production inputs and throughput. | Fast installation in assembly lines. |

| Versatility | Can be used in various industries and applications. | Facilitates diverse project requirements. | Applicable in automotive, aerospace, and construction sectors. |

| Cost-effectiveness | Reduces the need for costly repairs or replacements. | Lower total cost of ownership over time. | Minimizes downtime in production facilities. |

| Safety | Provides strong support that ensures worker safety. | Decreases workplace accidents and liabilities. | Safety regulations compliance in manufacturing. |

| Quality Assurance | Enhances the quality of manufactured products. | Higher product consistency leads to customer satisfaction. | Improved output quality in electronics manufacturing. |

| Sustainability | Supports sustainable practices by utilizing durable materials. | Longer lifespan reduces environmental impact. | Reducing waste in production processes. |

As we venture into 2025 and beyond, the design of frame support brackets is set for groundbreaking innovations that promise to redefine global manufacturing. One of the most significant shifts will be towards lightweight, high-strength materials that enhance durability while reducing overall weight. This change not only improves the structural integrity of various applications but also allows for greater energy efficiency during transportation and installation. Manufacturers are likely to adopt advanced materials such as carbon composites and specialized alloys, which will further bolster the performance and longevity of these essential components.

Additionally, the integration of smart technology into frame support bracket design will play a monumental role in the evolution of global manufacturing. With the rise of Industry 4.0, we can expect brackets that incorporate sensors and IoT capabilities, enabling real-time monitoring and predictive maintenance. This will minimize downtime and increase operational efficiency, leading to significant cost savings.

As companies increasingly prioritize sustainability, designs that support modular, easily recyclable brackets may also emerge, aligning manufacturing practices with eco-friendly initiatives while meeting the demands of an evolving market.