+86 13794985240

+86 13794985240

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

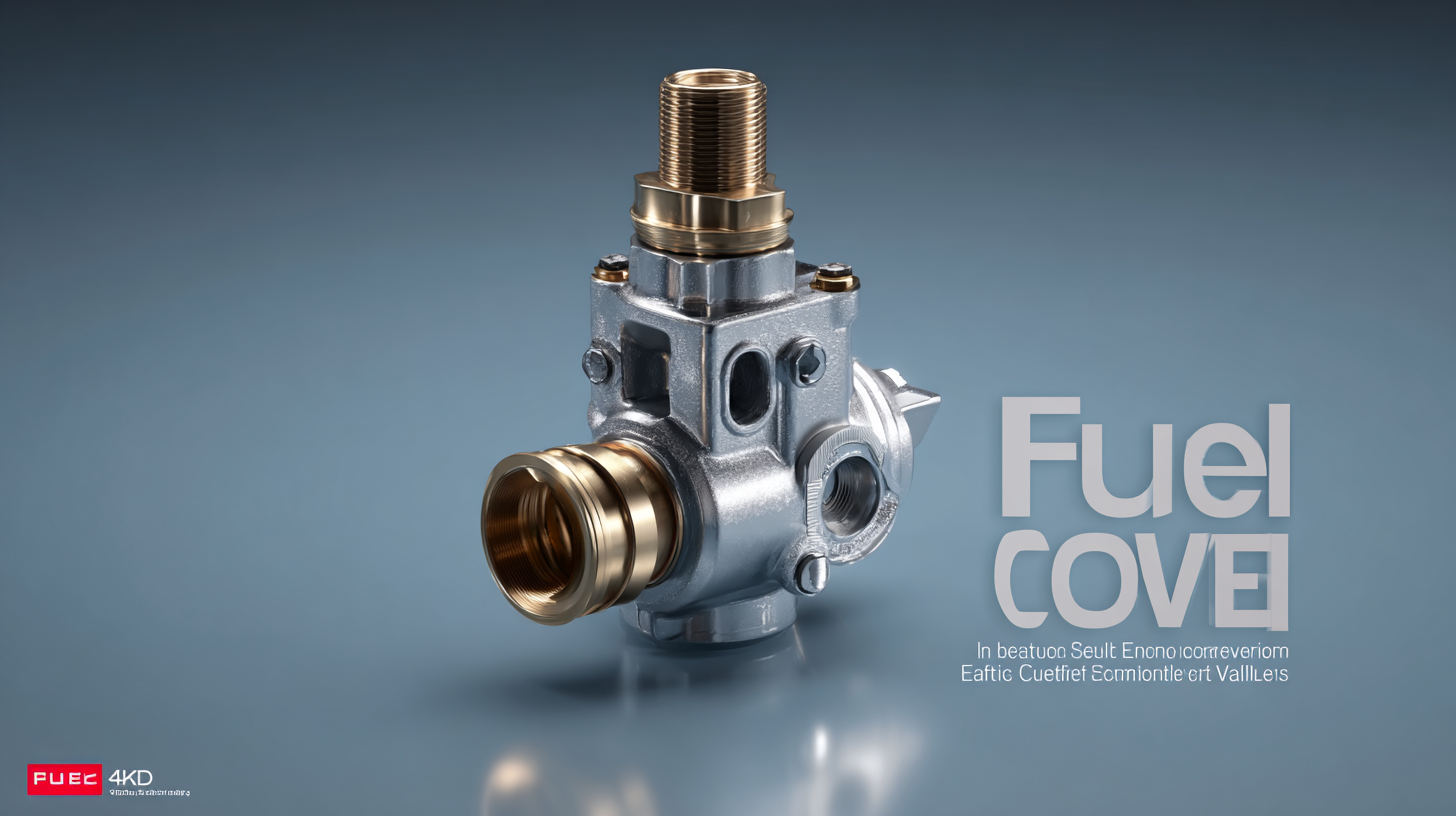

The optimization of industrial processes has become a critical focus in various sectors, particularly in the energy and manufacturing industries. According to a recent report by Markets and Markets, the global fuel control valves market is projected to reach $1.5 billion by 2025, driven by increasing demand for automation and enhanced efficiency. Fuel control valves play a pivotal role in regulating fuel flow and ensuring the optimal operation of machinery, thereby impacting overall performance metrics. As companies seek to minimize operational costs and maximize output, the integration of advanced technologies, such as digital monitoring and smart control systems, is essential.

This blog will explore innovative solutions to enhance efficiency through the application of best-in-class fuel control valves, aiming to provide insights on how improved technology and best practices can lead to significant performance gains in various applications.

Fuel control valves play a pivotal role in optimizing the efficiency of combustion systems across various industries. According to a report by the International Energy Agency (IEA), improving fuel efficiency can reduce energy consumption by up to 30% in industrial processes. This is particularly significant as businesses strive to cut costs and reduce their carbon footprint. Fuel control valves ensure precise regulation of fuel flow, which is crucial for maintaining optimal combustion conditions and achieving maximum energy output.

Fuel control valves play a pivotal role in optimizing the efficiency of combustion systems across various industries. According to a report by the International Energy Agency (IEA), improving fuel efficiency can reduce energy consumption by up to 30% in industrial processes. This is particularly significant as businesses strive to cut costs and reduce their carbon footprint. Fuel control valves ensure precise regulation of fuel flow, which is crucial for maintaining optimal combustion conditions and achieving maximum energy output.

When selecting fuel control valves, it is essential to consider factors such as valve type, materials, and compatibility with specific fuels. For instance, a recent study by the American Society of Mechanical Engineers (ASME) highlighted that using high-quality materials in valve construction can enhance resistance to corrosion and wear, thereby prolonging service life and decreasing maintenance costs. Regularly inspecting and calibrating these valves can further ensure they operate within optimal parameters, thereby minimizing fuel waste.

Tips for achieving the best performance from fuel control valves include regularly updating your systems with state-of-the-art technology that features advanced flow control capabilities. Additionally, implement routine maintenance schedules to avoid performance degradation, and ensure that your fuel supply is clean and consistent to prevent clogging and inefficient operation. By applying these strategies, organizations can significantly enhance their efficiency and sustainability.

When selecting high-quality fuel control valves, several key features should be prioritized to enhance operational efficiency. First and foremost, look for valves made from durable materials that can withstand corrosive environments and high pressures. Stainless steel and high-performance plastics are often ideal choices, ensuring longevity and reducing the need for frequent replacements. Additionally, the design of the valve should facilitate smooth flow control to minimize energy loss, which is essential for maintaining optimal fuel efficiency in any system.

Another crucial aspect is the valve's response time and precision. High-quality fuel control valves should offer rapid and accurate adjustments to fuel flow, allowing for real-time changes in operational requirements. Features like electronic actuation and smart technology integration can provide improved responsiveness and enhance overall system performance. Moreover, consider valves equipped with advanced sealing technologies to prevent leaks, further improving efficiency and reducing unnecessary wastage. By focusing on these essential features, businesses can ensure they select fuel control valves that meet their efficiency goals effectively.

| Feature | Description | Importance |

|---|---|---|

| Material Quality | High-grade materials ensure durability and resistance to wear. | Critical for the longevity of valves and minimizing downtime. |

| Flow Control Accuracy | Precision in regulating fuel flow for optimal engine performance. | Essential for efficiency and meeting emission standards. |

| Response Time | Speed at which the valve responds to control signals. | Affects engine responsiveness and fuel efficiency. |

| Compatibility | Ability to work with various fueling systems and configurations. | Important for integration into existing systems. |

| Maintenance Requirements | Ease of maintenance and servicing to ensure optimal operation. | Key for reducing total cost of ownership. |

| Pressure Rating | Maximum pressure the valve can withstand during operation. | Critical for safety and operational reliability. |

To ensure the optimal performance of fuel control valves, a comprehensive maintenance checklist is essential. Regular inspections should focus on various components, including actuator functionality, linkage integrity, and seal conditions. Checking for leaks is crucial, as even small leaks can lead to significant efficiency loss and operational safety issues. Additionally, measuring response times during operation can help identify any lag that may indicate the need for maintenance or adjustment.

Another critical aspect of maintenance is the calibration of the fuel control valves. Ensuring that they are accurately calibrated to match engine specifications helps maintain efficiency and performance. Operators should also clean the valves regularly to prevent blockages caused by carbon build-up or sediment. This step is vital to maintaining fluid dynamics and ensuring that the valves operate smoothly without obstruction, enhancing overall system efficiency. By following a consistent maintenance checklist, operators can extend the lifespan of fuel control valves and optimize performance, thereby reducing operational costs and improving fuel efficiency.

Fuel control valves (FCVs) are essential components in optimizing engine performance and fuel efficiency. However, they are not immune to common issues that can hinder their operation. Among these issues, blockage due to dirt and debris is prevalent, particularly in older systems where maintenance might have been neglected. According to a report by the Society of Automotive Engineers (SAE), nearly 30% of fuel system failures can be attributed to inadequate filtration, leading to reduced fuel flow and increased wear on engine components.

Another frequent problem is the degradation of the valve’s sealing surfaces, which can lead to fuel leakage and uneven fuel distribution. A study by the American Society of Mechanical Engineers (ASME) highlighted that approximately 20% of fuel control valves exhibit leakage past the seals over time, significantly impacting fuel efficiency and emissions. Regular inspection and timely replacement of worn parts can help mitigate these issues. Employing advanced diagnostic tools to monitor FCV performance and incorporating better fuel management practices can greatly enhance overall system reliability and efficiency.

In the realm of fuel management, innovative technologies in fuel control valves are pivotal in enhancing operational efficiency. Modern fuel control valves utilize advanced materials and smart design, allowing for precision in controlling fuel flow and pressure. These innovations not only reduce waste but also improve overall performance by ensuring optimal fuel distribution. The integration of electronic controls and sensors in fuel valves enables real-time monitoring and adjustments, which can significantly enhance the fuel combustion process.

Tips for selecting the right fuel control valve include considering the type of fuel being used, as different fuels have unique characteristics that can affect valve performance. Additionally, ensure that the valve is compatible with your existing systems to avoid costly retrofitting. Regular maintenance of your fuel control valves is crucial; a well-maintained valve can dramatically prolong equipment life and efficiency.

Moreover, look into valves that offer adjustable settings for varying operational requirements. This flexibility can lead to substantial savings on fuel costs while maintaining high levels of efficiency across different operational conditions. Implementing these innovative technologies in fuel control valves can transform your fuel management practices, leading to an overall enhancement in productivity.